Dostawcy Podkladki sprezyste, faliste i zakrzywione

Ten produkt podlega następującym normom:

DIN 137 (Equivalent standards: NF E 27620, UNI 8840) UNI 8840 NF E27-620

Dane techniczne

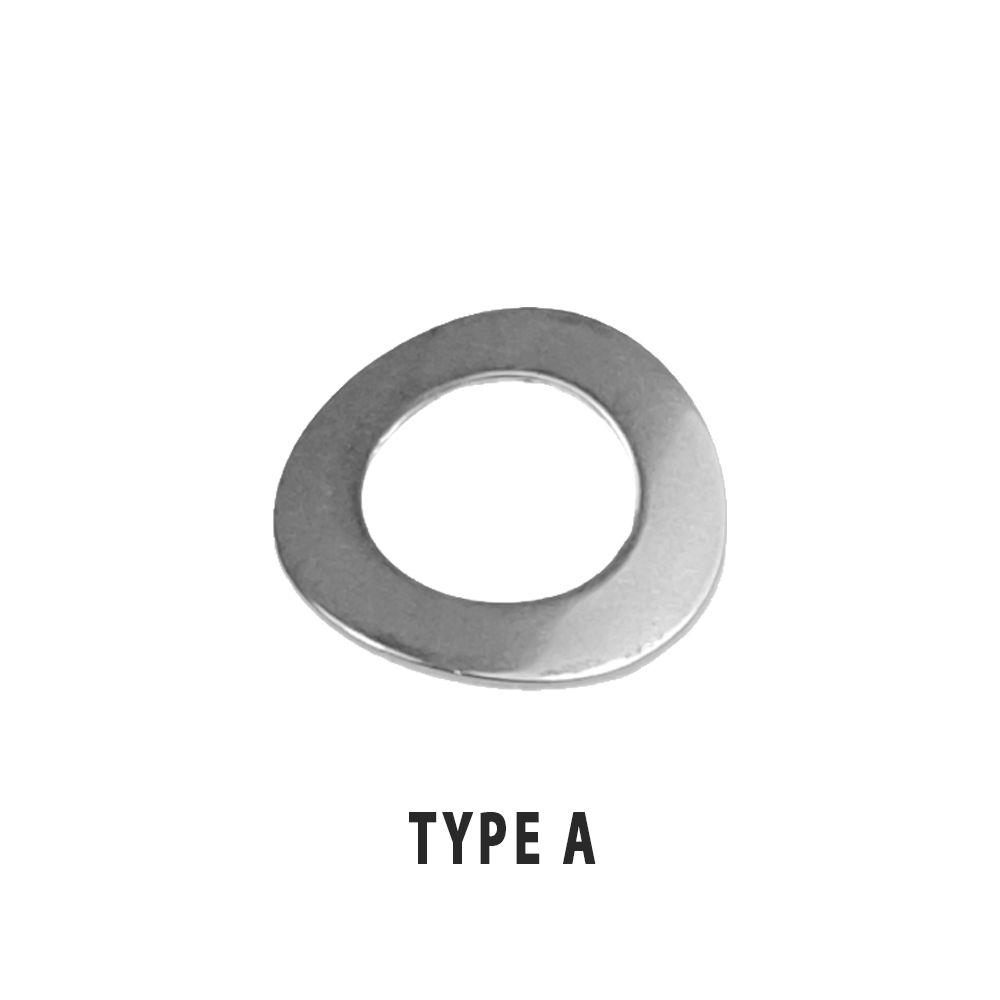

Podkladki sprezyste, faliste i zakrzywione

Ten produkt podlega następującym normom:

Standard DIN 137

- NF E 27620

- UNI 8840

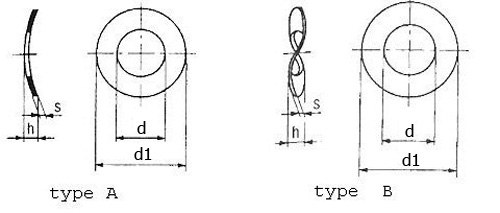

| Dimensions in mm - source DIN 137 A | ||||||||

| Date of publication: 1985 - Norm cancelled without replacement | ||||||||

| Thread size | d min/nom | d1 nom | h min | h max | s nom | ≈ mass in Kg x 1000 pcs (ρ=7,85 kg/dm3) | ||

| M 2 | 2.2 | 4.5 | 0.5 | 1 | 0.3 | 0.028 | ||

| M 2.3 | ||||||||

| M 2.5 | ||||||||

| M 3 | ||||||||

| M 3.5 | ||||||||

| M 4 | ||||||||

| M 5 | ||||||||

| M 6 | ||||||||

| M 7 | ||||||||

| M 8 | ||||||||

| M 10 | ||||||||

| Dimensions in mm - source DIN 137 B | ||||||||

| Date of publication: 1985 - Norm cancelled without replacement | ||||||||

| Thread size | d min/nom | d1 nom | h min | h max | s min | ≈ mass in Kg x 1000 pcs (ρ=7,85 kg/dm3) | ||

| M 3 | 3.2 | 8 | 0.8 | 1.6 | 0.5 | 0.166 | ||

| M 3.5 | ||||||||

| M 4 | ||||||||

| M 5 | ||||||||

| M 6 | ||||||||

| M 7 | ||||||||

| M 8 | ||||||||

| M 10 | ||||||||

| M 12 | ||||||||

| M 14 | ||||||||

| M 16 | ||||||||

| M 18 | ||||||||

| M 20 | ||||||||

| M 22 | ||||||||

| M 24 | ||||||||

Standard UNI 8840

Podkladki sprezyste zakrzywione i faliste. Seria s...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

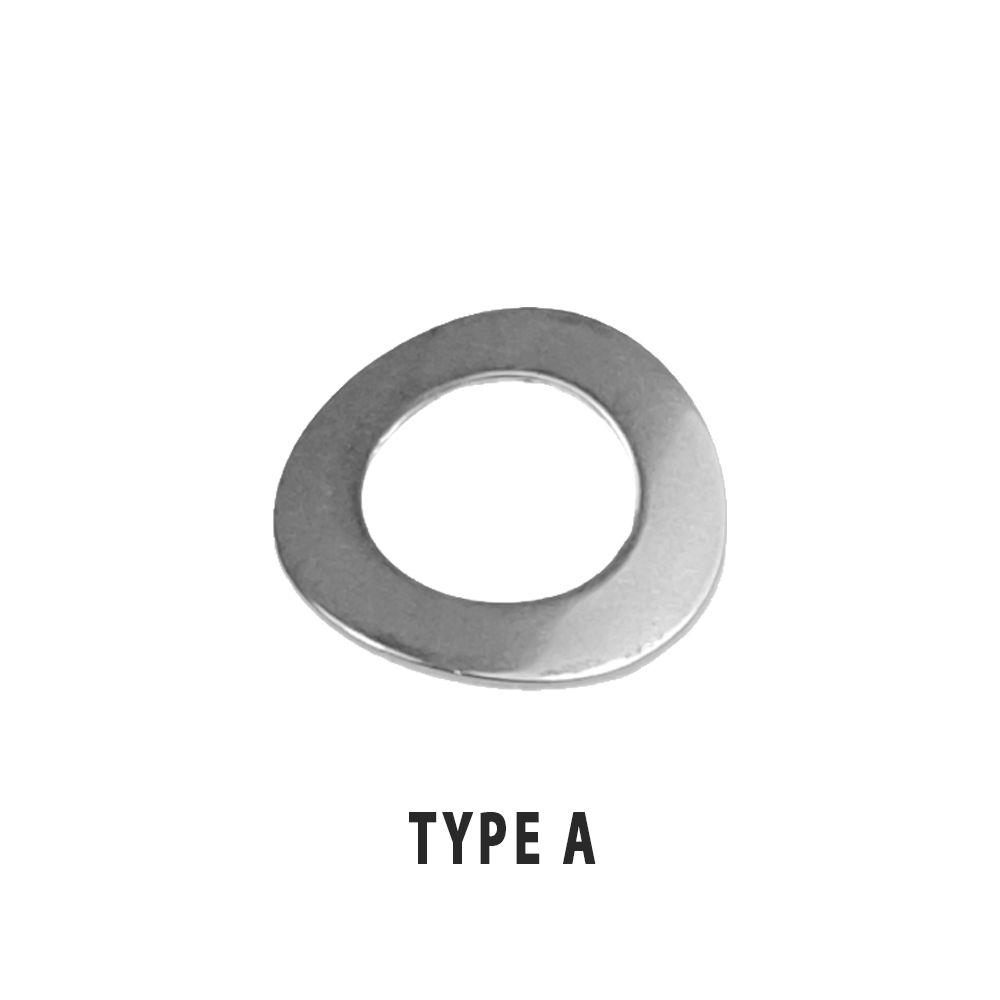

| Dimensions in mm - source UNI 8840 Typ A | ||||||||

| Date of publication: 04/1985 | ||||||||

| Thread size | d min/nom | d1 nom | h min | h max | s nom | |||

| M 2 | 2.2 | 4.5 | 0.5 | 1 | 0.3 | |||

| M 2.3 | ||||||||

| M 2.5 | ||||||||

| M 3 | ||||||||

| M 3.5 | ||||||||

| M 4 | ||||||||

| M 5 | ||||||||

| M 6 | ||||||||

| M 7 | ||||||||

| M 8 | ||||||||

| Dimensions in mm - source UNI 8840 Typ A | ||||||||

| Date of publication: 04/1985 | ||||||||

| Thread size | d min/nom | d1 nom | h min | h max | s min | |||

| M 3 | 3.2 | 8 | 0.8 | 1.6 | 0.5 | |||

| M 3.5 | ||||||||

| M 4 | ||||||||

| M 5 | ||||||||

| M 6 | ||||||||

| M 7 | ||||||||

| M 8 | ||||||||

| M 10 | ||||||||

| M 12 | ||||||||

| M 14 | ||||||||

| M 16 | ||||||||

| M 18 | ||||||||

| M 20 | ||||||||

| M 22 | ||||||||

| M 24 | ||||||||

| M 27 | ||||||||

| M 30 | ||||||||

| M 33 | ||||||||

| M 36 | ||||||||

Standard NF E27-620

Podkladki sprezyste, 2 faleInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!Szczegóły

Podkladki sprezyste, faliste i zakrzywione

|

Wymiary w mm - zródlo DIN 137 A |

||||||||

| Data publikacji: 1985 - Norma anulowana bez zastapienia | ||||||||

|

Rozmiar gwintu

|

d min/nom |

d1 nom |

h min | h max |

s ≈ masa w kg x 1000 szt. (ρ=7,85 kg/dm3) |

| ||

|

M 2

|

2,2

|

4,5

|

0,5

|

1

|

0,3 | 0,028 | ||

|

M 2,3

|

2,5

|

5

|

0,5

|

1

|

0,3 | 0,035 | ||

|

M 2,5

|

2,8

|

5,5

|

0,55

|

1,1

|

0,3 | 0,041 | ||

|

M 3

|

3,2

|

6

|

0,65

|

1,3

|

0,4 | 0,063 | ||

|

M 3,5

|

3,7

|

7

|

0,7

|

1,4

|

0,4 | 0,088 | ||

|

M 4

|

4,3

|

8

|

0,8

|

1,6

|

0,5 | 0,14 | ||

|

M 5

|

5,3

|

10

|

0,9

|

1,8

|

0,5 | 0,222 | ||

|

M 6

|

6,4

|

11

|

1.1

|

2.2

|

0.5 | 0,247 | ||

|

M 7

|

7,4

|

12

|

1,2

|

2,4

|

0,5 | 0,361 | ||

|

M 8

|

8,4

|

15

|

1,7

|

3,4

|

0,5 | 0,476 | ||

|

M 10

|

10,5

|

18

|

2

|

4

|

0,8 | 1,05 | ||

|

Wymiary w mm - zródlo DIN 137 B |

||||||||

| Data publikacji: 1985 - Norma anulowana bez zastapienia | ||||||||

| Rozmiar gwintu |

d min/nom |

d1 nom |

h min | h max | s min | ≈ masa w kg x 1000 szt. (ρ=7,85 kg/dm3) | ||

|

M 3

|

3,2

|

8

|

0,8 | 1,6 |

0,5

|

0,166 | ||

|

M 3,5

|

3,7

|

8

|

0,9 | 1,8 |

0,5

|

0,154 | ||

|

M 4

|

4.3

|

9

|

1 | 2 |

0,5

|

0,193 | ||

|

M 5

|

5,3

|

11

|

1,1 | 2,2 |

0,5

|

0,286 | ||

|

M 6

|

6,4

|

12

|

1,3 | 2,6 |

0,5

|

0,318 | ||

|

M 7

|

7,4

|

14

|

1,5 | 3 |

0,8

|

0,535 | ||

|

M 8

|

8,4

|

15

|

1,5 | 3 |

0,8

|

0,76 | ||

|

M 10

|

10,5

|

21

|

2,1 | 4,2 |

1

|

2.04 | ||

|

M 12

|

13

|

24

|

2,5 | 5 |

1,2

|

3.01 | ||

|

M 14

|

15

|

28,0

|

3 | 6 |

1,6

|

5,17 | ||

|

M 16

|

17

|

30

|

3,2 | 6,4 |

1,6

|

5,65 | ||

|

M 18

|

19

|

34

|

3.3 | 6,6 |

1,6

|

7,35 | ||

|

M 20

|

21

|

36

|

3,7 | 7,4 |

1,6

|

8,43 | ||

|

M 22

|

23

|

40

|

3,9 | 7,8 |

1,8

|

11,9 | ||

|

M 24

|

25

|

44

|

4,1 | 8,2 |

1,8

|

14,5 | ||

Pełna lista dostawców Podkladki sprezyste, faliste i zakrzywione

Leading manufacturer of stainless steel washers and compensation rings for ball bearings. Standard and special parts.

Manufacturer of rings, rings for radial assembly, rings for compensating axial play, uniform section snap rings, push-on fix/grip rings, wire rings, shim and support rings

ISO/TS 16949:2002

Biggest factory in China producing stainless steel washers.

Fat washers, spring washers, tooth lock washers and stamping parts.

Materials: 316L ,316S33,1.4462.

Manufacturer of blind rivets, solid rivets, fully tubular rivets, semi tubular rivets, bifurcated rivets

Distributor of retaining rings, Spiral retaining rings, wave springs, Disc springs, Washers, Elastic pins, Pins, Keys, Ground flat/bar stocks, Locking nuts, washers, Miniplast plastic parts, Metallic screws, nuts, bolts.

Manufacturer of washers, disc springs, wave spring washers, serrated safety washers, Belleville washers, serrated washers & lockrite washers.

Production and sales of disc springs, disc washers, waveform springs, diaphragm springs, special-shaped springs and other high-quality elastic components.

Manufacturer of precision products: retaining components, spring washers and stampings

Manufacturer of flat washers standard and specials, UNC/SAE/STD, special washers and stampings

Manufacturer of retaining rings, starlock washers, toothed washers, slotted spring pins, quick fixings and special parts

Manufacturer specialized in washers. Production of 200,000 washers/day.

Flat, spring, toothed, square and wave washers, etc...

Manufacturer of coil springs and distributor of disc springs, circlips,retaining rings, hose clamps, tool clips, retaining pins and linch pins, push on fasteners, shims and spring washers and split key rings.

Manufacturer of washers and stamped parts in stainless steel, brass, copper, silicon bronze, aluminum

Manufacturer of snap and retaining rings, toothed washers and spring pins. Metric and inch sizes.