Dostawcy Podkladki zabezpieczajace dzielone

Ten produkt podlega następującym normom:

Dane techniczne

Podkladki zabezpieczajace dzielone

Ten produkt podlega następującym normom:

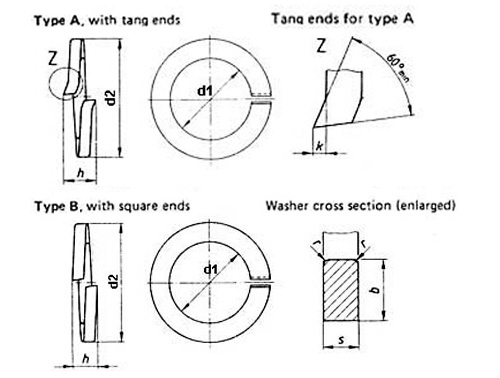

Standard DIN 127

Podkladki sprezyste dzielone z trzpieniem typu A i...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

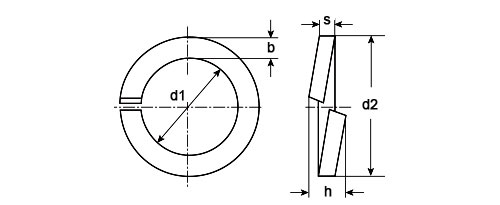

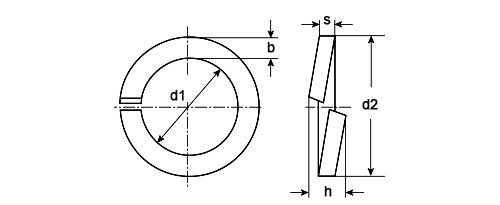

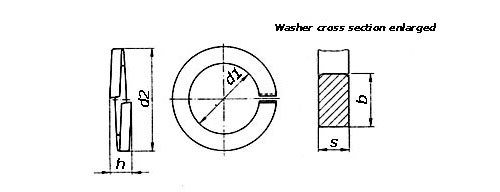

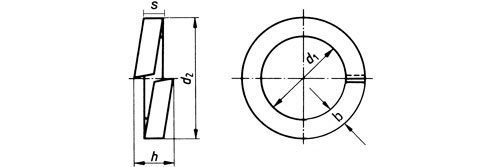

| Dimensions in mm - source DIN 127 A & B Withdrawn | ||||||||||||

| Publication date: 10/1987 - Supersedes 12/1970 | ||||||||||||

| Nominal size | Thread size | d1 min. | d2 max | b nom | s nom | k | r | h | ≈ weight in Kg x 1000 pcs (ρ=7,85 kg/dm3) | |||

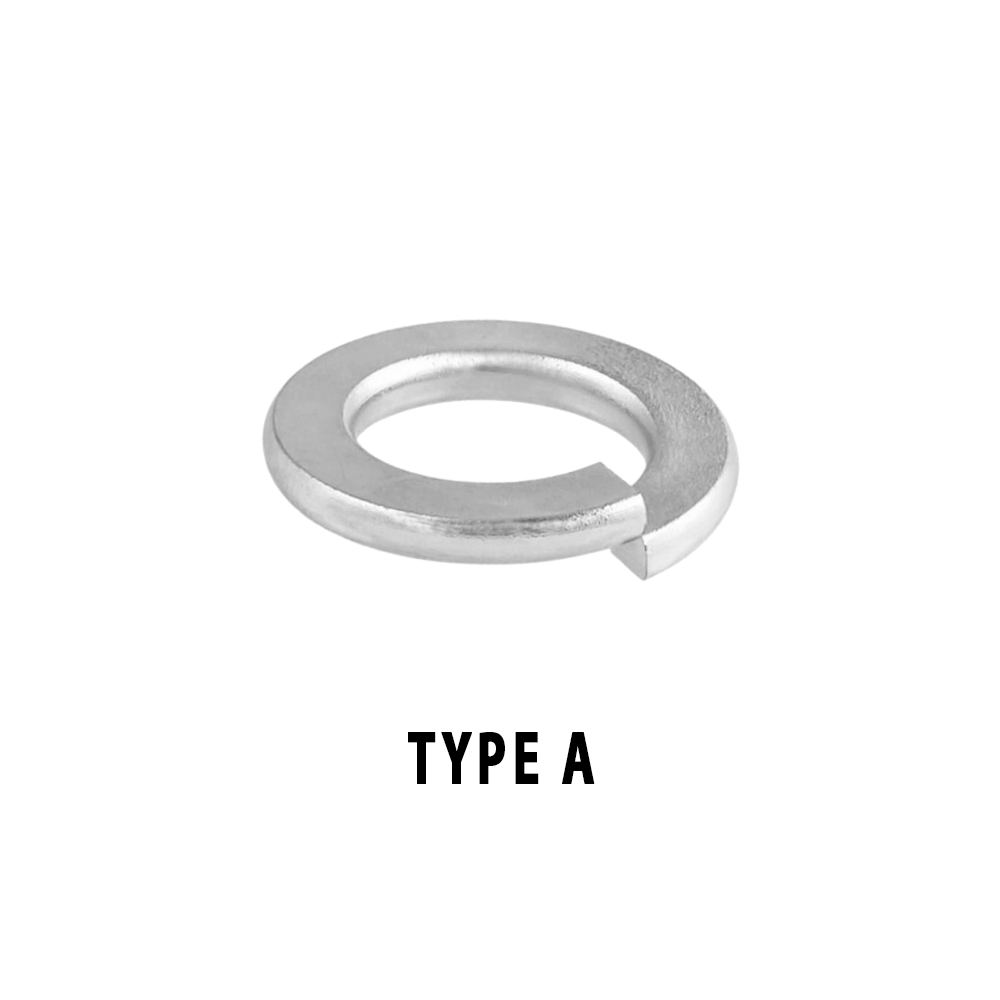

| Type A | Type B | |||||||||||

| min. | max. | min. | max. | |||||||||

| 2 | M 2 | 2.1 | 4.4 | 0.9 | 0.5 | - | 0.1 | - | - | 1 | 1.2 | 0.033 |

| 2.2 | M 2.2 | 2.3 | 4.8 | 1 | 0.6 | - | 0.1 | - | - | 1.2 | 1.4 | 0.05 |

| 2.5 | ||||||||||||

| 3 | ||||||||||||

| 3.5 | ||||||||||||

| 4 | ||||||||||||

| 5 | ||||||||||||

| 6 | ||||||||||||

| 7 | ||||||||||||

| 8 | ||||||||||||

| 10 | ||||||||||||

| 12 | ||||||||||||

| 14 | ||||||||||||

| 16 | ||||||||||||

| 18 | ||||||||||||

| 20 | ||||||||||||

| 22 | ||||||||||||

| 24 | ||||||||||||

| 27 | ||||||||||||

| 30 | ||||||||||||

| 36 | ||||||||||||

| 39 | ||||||||||||

| 42 | ||||||||||||

| 45 | ||||||||||||

| 48 | ||||||||||||

| 52 | ||||||||||||

| 56 | ||||||||||||

| 60 | ||||||||||||

| 64 | ||||||||||||

| 68 | ||||||||||||

| 72 | ||||||||||||

| 80 | ||||||||||||

| 90 | ||||||||||||

| 100 | ||||||||||||

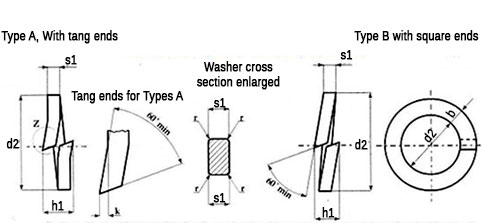

Standard UNI 1751

Podkladki sprezynowe jednozwojowe - seria normalna...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source UNI 1751 | ||||||||||||

| Publication date: 01/1988 - Supersedes 12/1970 | ||||||||||||

| Thread size | d1 | d2 max | b nom | s1 nom | r | k | h1 | ≈ weight in Kg x 1000 pcs (ρ=7,85 kg/dm3) | ||||

| Type A | Type B | |||||||||||

| max | min | min. | max. | min. | max. | |||||||

| M 2 | 2.1 | 2.4 | 4.4 | 0.9 | 0.5 | 0.1 | - | - | - | 1 | 1.2 | 0.033 |

| M 2.2 | 2.3 | 2.6 | 4.8 | 1 | 0.6 | 0.1 | - | - | - | 1.2 | 1.4 | 0.05 |

| M 2.5 | 2.6 | 2.9 | 5.1 | 1 | 0.6 | 0.1 | - | - | - | 1.2 | 1.4 | 0.053 |

| M 3 | ||||||||||||

| M 3.5 | ||||||||||||

| M 4 | ||||||||||||

| M 5 | ||||||||||||

| M 6 | ||||||||||||

| M 7 | ||||||||||||

| M 8 | ||||||||||||

| M 10 | ||||||||||||

| M 12 | ||||||||||||

| M 14 | ||||||||||||

| M 16 | ||||||||||||

| M 18 | ||||||||||||

| M 20 | ||||||||||||

| M 22 | ||||||||||||

| M 24 | ||||||||||||

| M 27 | ||||||||||||

| M 30 | ||||||||||||

| M 33 | ||||||||||||

| M 36 | ||||||||||||

| M 39 | ||||||||||||

| M 42 | ||||||||||||

| M 45 | ||||||||||||

| M 48 | ||||||||||||

| M 52 | ||||||||||||

| M 56 | ||||||||||||

| M 60 | ||||||||||||

| M 64 | ||||||||||||

| M 68 | ||||||||||||

| M 72 | ||||||||||||

| M 80 | ||||||||||||

| M 90 | ||||||||||||

| M 100 | ||||||||||||

| Dimensions in mm-Split lock washers commercial type | ||||||

| Nominal size | Thread size | d | b | s | D | ≈ weight in Kg x 1000 pcs (ρ=7,85 kg/dm3) |

| 3.2 | ||||||

| 4.3 | ||||||

| 5.3 | ||||||

| 6.4 | ||||||

| 7.4 | ||||||

| 8.4 | ||||||

| 10.5 | ||||||

| 12.5 | ||||||

| 15 | ||||||

| 17 | ||||||

| 19 | ||||||

| 21 | ||||||

| 23 | ||||||

| 25 | ||||||

| 28 | ||||||

| Dimensions in mm-Split lock washers heavy type | ||||||

| nominal size | thread size | d | b | s | D | ≈ weight in Kg x 1000 pcs (ρ=7,85 kg/dm3) |

| 3.2 | ||||||

| 4.2 | ||||||

| 5.2 | ||||||

| 6.3 | ||||||

| 7.3 | ||||||

| 8.3 | ||||||

| 10.4 | ||||||

| 12.4 | ||||||

| 14.5 | ||||||

| 16.6 | ||||||

| 18.6 | ||||||

| 20.6 | ||||||

| 22.7 | ||||||

| 24.7 | ||||||

Standard NF E25-515

Podkladki sprezyste standardowe serii W SymbolInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source NF E 25515 regular series - Withdrawn Publication date: 05-1986 | |||||

| thread size | d1 nom | d2 nom | b nom | s nom | h |

| M 3 | 3.5 | 5.2 | 1 | 1 | ≈2s |

| M 4 | 4.5 | 7.3 | 1.5 | 1.5 | ≈2s |

| M 5 | 5.5 | 8.3 | 1.5 | 1.5 | ≈2s |

| M 6 | 6.5 | 10.4 | 2 | 2 | ≈2s |

| M 7 | |||||

| M 8 | |||||

| M 10 | |||||

| M 12 | |||||

| M 14 | |||||

| M 16 | |||||

| M 18 | |||||

| M 20 | |||||

| M 22 | |||||

| M 24 | |||||

| M 27 | |||||

| M 30 | |||||

| M 33 | |||||

| M 36 | |||||

| M 39 | |||||

| M 42 | |||||

| M 45 | |||||

| M 48 | |||||

| M 52 | |||||

| M 56 | |||||

| M 60 | |||||

| M 64 | |||||

| M 68 | |||||

| M 72 | |||||

| M 76 | |||||

| M 80 | |||||

Standard NF E25-516

Podkladki sprezynowe jednozwojowe. Mala seria. Sym...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source NF E 25516 light series Publication date: 06-2009 | |||||

| thread size | d1 nom | d2 nom | b nom | s nom | h |

| M 3 | 3.5 | 5.2 | 1 | 0.6 | ≈2s |

| M 4 | 4.5 | 7.3 | 1.5 | 1 | ≈2s |

| M 5 | |||||

| M 6 | |||||

| M 7 | |||||

| M 8 | |||||

| M 10 | |||||

| M 12 | |||||

| M 14 | |||||

| M 16 | |||||

| M 18 | |||||

| M 20 | |||||

| M 22 | |||||

| M 24 | |||||

| M 27 | |||||

| M 30 | |||||

Standard NF E25-517

Podkladki sprezynowe jednozwojowe – seria mocna – ...Informacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source NF E25-517 | |||||||||

| Publication date: 06-2009 | |||||||||

| Thread size | d1 min. | d1 max | d2≈ | b min | b max | s min | s max | h ≈2s | ≈ weight in Kg x 1000 pcs (ρ=7,85 kg/dm3) |

| M 3 | 3.50 | 3.98 | 6.20 | 1.30 | 1.70 | 0.80 | 1.20 | 2.00 | 0.18 |

| M 4 | |||||||||

| M 5 | |||||||||

| M 6 | |||||||||

| M 7 | |||||||||

| M 8 | |||||||||

| M 10 | |||||||||

| M 12 | |||||||||

| M 14 | |||||||||

| M 16 | |||||||||

| M 18 | |||||||||

| M 20 | |||||||||

| M 22 | |||||||||

| M 24 | |||||||||

Standard BS 4464 B

Podkladki sprezysteInformacje zastrzeżone dla zarejestrowanych użytkowników: Zaloguj się | Zarejestruj się i rozpocznij 14 dniowy okres próbny!

| Dimensions in mm - source BS 4464 Table B | ||||||

| Publication Date: 05/1969 |

| Thread size | d1 min | d2 max | b min | b max | s min | s max |

| M 3 | 3.1 | 5.5 | 1.2 | 1.4 | 0.7 | 0.9 |

| M 3.5 | 3.6 | 6 | 1.2 | 1.4 | 0.7 | 0.9 |

| M 4 | ||||||

| M 5 | ||||||

| M 6 | ||||||

| M 8 | ||||||

| M 10 | ||||||

| M 12 | ||||||

| M 14 | ||||||

| M 16 | ||||||

| M 18 | ||||||

| M 20 | ||||||

| M 22 | ||||||

| M 24 | ||||||

| M 27 | ||||||

| M 30 | ||||||

| M 33 | ||||||

| M 36 | ||||||

| M 39 | ||||||

| M 42 | ||||||

| M 45 | ||||||

| M 48 | ||||||

Szczegóły

Podkladki zabezpieczajace dzielone

|

Wymiary w mm - zródlo: DIN 127 A i B |

||||||||||||

| Data publikacji: 10/1987 - Zastepuje wydanie z 12/1970. - Norma anulowana bez zastapienia | ||||||||||||

| Rozmiar nominalny |

Rozmiar gwintu

|

d1 min.

|

d2 max

|

b nom

|

s nom | k | r | h |

≈ waga w kg x 1000 szt. (ρ=7,85 kg/dm3)

|

|||

| Typ A | Typ B | |||||||||||

| min. | maks. | min. | maks. | |||||||||

|

2

|

M 2

|

2,1

|

4,4

|

0,9

|

0,5 | - | 0,1 |

-

|

-

|

1

|

1,2

|

0,033

|

|

2,2

|

M 2,2

|

2,3

|

4,8

|

1

|

0,6 | - | 0,1 |

-

|

-

|

1,2

|

1,4

|

0,05

|

|

2,5

|

M 2,5

|

2,6

|

5,1

|

1

|

0,6 | - | 0,1 |

-

|

-

|

1.2

|

1.4

|

0,053

|

|

3

|

M 3

|

3,1

|

6,2

|

1,3

|

0,8 | 0,15 | 0,2 |

1,9

|

2,1

|

1,6

|

1,9

|

0,11

|

|

3,5

|

M 3,5

|

3,6

|

6,7

|

1,3

|

0,8 | 0,15 | 0,2 |

1,9

|

2,2

|

1,6

|

1,9

|

0,12

|

|

4

|

M 4

|

4,1

|

7,6

|

1,5

|

0,9 | 0,15 | 0,2 |

2,1

|

2,5

|

1,8

|

2,1

|

0,18

|

|

5

|

M 5

|

5.1

|

9.2

|

1,8

|

1,2 | 0,15 | 0,2 |

2,7

|

3,2

|

2,4

|

2,8

|

0,36

|

|

6

|

M 6

|

6,1

|

11,8

|

2,5

|

1,6 | 0,2 | 0,3 |

3,6

|

4,2

|

3,2

|

3,8

|

0,83

|

|

7

|

M 7

|

7.1

|

12.8

|

2.5

|

1.6 | 0,2 | 0,3 |

3,6

|

4,2

|

3,2

|

3,8

|

0,93

|

|

8

|

M 8

|

8,1

|

14,8

|

3

|

2 | 0,3 | 0,5 |

4,6

|

5,4

|

4

|

4,7

|

1,6

|

|

|

|

|

|

3,5

|

2,2 | 0,3 | 0,5 |

5

|

5,9

|

4,4

|

5,2

|

2,53

|

|

12

|

M 12

|

12,2

|

21,1

|

4

|

2,5 | 0,4 | 1 |

5,8

|

6,6

|

5

|

5,9

|

3,82

|

|

14

|

M 14

|

14,2

|

24,1

|

4,5

|

3 | 0,4 | 1 |

6,5

|

8

|

6

|

7.1

|

6.01

|

|

16

|

M 16

|

16,2

|

27,4

|

5

|

3,5 | 0,4 | 1 |

7,8

|

9,2

|

7

|

8,3

|

8,91

|

|

18

|

M 18

|

18,2

|

29,4

|

5

|

3,5 | 0,4 | 1 |

7,8

|

9,2

|

7

|

8,3

|

9,73

|

|

20

|

M 20

|

20,2

|

33,6

|

6

|

4 | 0,4 | 1 |

8,8

|

10,4

|

8

|

9,4

|

15,2

|

|

22

|

M 22

|

22,5

|

35,9

|

6

|

4 | 0,4 | 1 |

8,8

|

10,4

|

8

|

9,4

|

16,5

|

|

24

|

M 24

|

24,5

|

40

|

7

|

5 | 0,5 | 1,6 |

11

|

13

|

10

|

11,8

|

26,2

|

|

27

|

M 27

|

27,5

|

43

|

7

|

5 | 0,5 | 1,6 |

11

|

13

|

10

|

11,8

|

28,7

|

|

30

|

M 30

|

30,5

|

48,2

|

8

|

6 | 0,8 | 1,6 |

13,6

|

16,1

|

12

|

14,2

|

44,3

|

|

36

|

M 36

|

36,5

|

58,2

|

10

|

6 | 0,8 | 1,6 |

13,6

|

16,1

|

12

|

14,2

|

67,3

|

|

39

|

M 39

|

39,5

|

61,2

|

10

|

6 | 0,8 | 1,6 |

13,6

|

16,1

|

12

|

14,2

|

71,7

|

|

42

|

M 42

|

42,5

|

68,2

|

12

|

7 | 0,8 | 2 |

15,6

|

18,4

|

14

|

16,5

|

111

|

|

45

|

M 45

|

45,5

|

71,2

|

12

|

7 | 0,8 | 2 |

15,6

|

18,4

|

14

|

16,5

|

117

|

|

48

|

M 48

|

49

|

75

|

12

|

7 | 0,8 | 2 |

15,6

|

18,4

|

14

|

16,5

|

123

|

|

52

|

M 52

|

53

|

83

|

14

|

8 | 1 | 2 |

18

|

21,2

|

16

|

18,9

|

182

|

|

56

|

M 56

|

57

|

87

|

14

|

8 | 1 | 2 |

18

|

21,2

|

16

|

18,9

|

193

|

|

60

|

M 60

|

61

|

91

|

14

|

8 | 1 | 2 |

18

|

21.2

|

16

|

18,9

|

203

|

|

64

|

M 64

|

65

|

95

|

14

|

8 | 1 | 2 |

18

|

21.2

|

16

|

18,9

|

218

|

|

68

|

M 68

|

69

|

99

|

14

|

8 | 1 | 2 |

18

|

21,2

|

16

|

18,9

|

228

|

|

72

|

M 72

|

73

|

103

|

14

|

8 | 1 | 2 |

18

|

21,2

|

16

|

18,9

|

240

|

|

80

|

M 80

|

81

|

111

|

14

|

8 | 1 | 2 |

18

|

21,2

|

16

|

18,9

|

262

|

|

90

|

M 90

|

91

|

121

|

14

|

8 | 1 | 2 |

18

|

21.2

|

16

|

18,9

|

290

|

|

100

|

M 100

|

101

|

131

|

14

|

8 | 1 | 2 |

18

|

21.2

|

16

|

18,9

|

318

|

|

Wymiary w mm - zródlo NF E 25515, seria regularna |

||||||

| rozmiar gwintu | d1 nom | d2 nom | b nom | s |

h

|

|

| M 3 | 3,5 | 5,2 | 1 | 1 | 1 | ≈2s |

| M 4 | 4,5 | 7,3 | 1,5 | 1,5 | ≈2s | |

| M 5 | 5,5 | 8,3 | 1,5 | 1,5 | ≈2s | |

| M 6 | 6,5 | 10.4 | 2 | 2 | ≈2s | |

| M 7 | 7,5 | 11,4 | 2 | 2 | ≈2s | |

| M 8 | 8,5 | 13,4 | 2,5 | 2,5 | ≈2s | |

| M 10 | 10,5 | 16,5 | 3 | 3 | 3 | ≈2s |

| M 12 | 13 | 20 | 3,5 | 3,5 | ≈2s | |

| M 14 | 15 | 23 | 4 | 4 | ≈2s | |

| M 16 | 17 | 25 | 4 | 4 | ≈2s | |

| M 18 | 19 | 28 | 5 | 5 | ≈2s | |

| M 20 | 21 | 31 | 5 | 5 | ≈2s | |

| M 22 | 23 | 33 | 5 | 5 | ≈2s | |

| M 24 | 25 | 37 | 6 | 6 | 6 | ≈2s |

| M 27 | 28 | 40 | 6 | 6 | ≈2s | |

| M 30 | 31 | 45 | 7 | 7 | ≈2s | |

| M 33 | 34 | 48 | 7 | 7 | ≈2s | |

| M 36 | 37 | 53 | 8 | 8 | ≈2s | |

| M 39 | 40 | 56 | 8 | 8 | ≈2s | |

| M 42 | 43 | 61 | 9 | 9 | ≈2s | |

| M 45 | 46 | 64 | 9 | 9 | 9 | ≈2s |

| M 48 | 49 | 69 | 10 | 10 | ≈2s | |

| M 52 | 54 | 74 | 10 | 10 | ≈2s | |

| M 56 | 58 | 80 | 11 | 11 | ≈2s | |

| M 60 | 62 | 84 | 11 | 11 | ≈2s | |

| M 64 | 66 | 90 | 12 | 12 | ≈2s | |

| M 68 | 70 | 94 | 12 | 12 | 12 | ≈2s |

| M 72 | 74 | 100 | 13 | 13 | ≈2s | |

| M 76 | 78 | 104 | 13 | 13 | ≈2s | |

| M 80 | 82 | 110 | 14 | 14 | ≈2s | |

|

Wymiary w mm - zródlo NF E 25516 seria lamp |

|||||

| rozmiar gwintu | d1 nom | d2 nom | b nom |

s nom

|

h |

| 3 | 3,5 | 5,2 | 1 | 0,6 | ≈2s |

| 4 | 4,5 | 7,3 | 1,5 | 1 | ≈2s |

| 5 | 5,5 | 8,3 | 1,5 | 1 | ≈2s |

| 6 | 6,5 | 10,4 | 2 | 1,2 | ≈2s |

| 7 | 7,5 | 11,4 | 2 | 1,2 | ≈2s |

| 8 | 8,5 | 13,4 | 2,5 | 1,5 | ≈2s |

| 10 | 10,5 | 16,5 | 3 | 1,8 | ≈2s |

| 12 | 13 | 20 | 3,5 | 2 | ≈2s |

| 14 | 15 | 23 | 4 | 2,5 | ≈2s |

| 16 | 17 | 25 | 4 | 2,5 | ≈2s |

| 18 | 19 | 28 | 5 | 3 | ≈2s |

| 20 | 21 | 31 | 5 | 3 | ≈2s |

| 22 | 23 | 33 | 5 | 3 | ≈2s |

| 24 | 25 | 37 | 6 | 3,5 | ≈2s |

| 27 | 28 | 40 | 6 | 3,5 | ≈2s |

| 30 | 31 | 45 | 7 | 4,5 | ≈2s |

Pełna lista dostawców Podkladki zabezpieczajace dzielone

Company leader in the commerce of nuts, bolts.

Range of more than 100.000 products such as screws, bolts, technical articles, industrial wheels, Tie rods for ropes and tools.

pgb-Europe is one of the leading enterprises in fasteners in the Benelux and has its own production facilities in Poland.

- product range of +35K products

- state-of-the-art logistics

- uniform packaging

- flexible order processing via pgb-europe.com

- high quality products and ETA and CE marking

- CBAM authorised declarant since 10/2025

Wholesaler and distributor of high quality fasteners

Wholesaler/distributor of screws, nuts and bolts built in different materials, from plain steel to high resistance steel, to stainless steel and brass

Fasteners for: automobile, ironwork, furniture, producers of aluminum & PVC carpentry, agricultural machinery, mechanical engineering, fine mechanics, wood, metallic structures, food, energetic, chemical, petrochemical, gas, nuclear, nautical.

Founded in 1969, Buora D.P.U. is a distributor certified following ISO 9001.

The company offers the complete range of high strength fasteners, ready on stock, both coarse and fine pitches with metric and inch threads.

Distributor of prestigious brands such as UNBRAKO and NORD-LOCK, for Buora D.P.U. the service always comes first, therefore there is not minimum quantity required.

Distributor of fasteners and tools. 9 warehouses (for a total capacity of 60000 pallet places) are located in northern Italy, working with the industry and retail.

Kanban, consignment stock, vending machines are the services we provide.

Leading manufacturer of stainless steel washers and compensation rings for ball bearings. Standard and special parts.

Manufacturing and distribution of self tapping bushings, WTI helical inserts, grooved pins, grooved nails, expansion rivets and nails with grooves Kerpin®, trilobular threaded inserts, self clinching studs, standard and customized fasteners.

Manufacturer of plates and corner braces for ironmongery, shelves, brackets, blades for wall unit bracket, plates for gazebo, plastic items etc...

Production of washers in different sizes and norms

Leading manufacturer and supplier of a broad range of fasteners for numerous industrial branches. Owing to the high quality, durability and precise craftsmanship, our products are appreciated by numerous companies from the furniture, construction, electrotechnical and automotive sectors.

We hold a strong position on the domestic and European markets.

Manufacturer of solid, half-tubular rivets, pins.

Trader of rivets and fasteners.

The company Weyland-Steiner is a flexible supplier of norm, standard, drawing and special parts, as well as C-parts management!

Our strength is the rapid procurement of special parts in all materials and surfaces.

Full-service trader of tools, fittings and hardware.

Supplier of nuts, bolts and special drawing parts, both forged and turned.

UNI EN ISO 9001:2015 certified company.

Manufacturer of blind rivets, rivet nuts, pneumatic tools and washers. Distributor & importer of fasteners.

Distributor of blind rivets, speed rivets, blind nuts, lock bolts and clinching fasteners

Manufacturer of solid & blind rivets, blind bolts & installation tooling for the aerospace industry.

Manufacturer of axes, rivets and screws special plan for the automotive and general industry

Manufacturer of retaining rings for shaftsand bores- Din 47; Din 472 mm and inches. Toothed washers.

Quality certificates: ISO/TS 16949-2009; ISO 9001-2008

Manufacturer of standard and special bolts, studs and rivets by cold forming in the following material classes: 4,6 - 5,8 - 6,8 - 8,8 - 9,8 - 10,9 - 12,9.

Manufacturer and distributor of thumb screws, knurled nuts, clevis pins and dowel pins.

BSC CORPORATION LTD is a group founded in 2005, headquartered in Shanghai and developed in two factories, respectively located in Xinghua, Jiangsu province and Liaocheng, Shandong province.

The company is specialized in washers, stamping parts and other kinds of fasteners. The registered capital amounts to 50 million yuan.

Manufacturer of solid rivets, semi tubular rivets, fully tubular rivets, self piercing rivets and a wide range of customer specific fasteners

Manufacturer of rivets, blind rivets, riveting machines and self drilling screws

Manufacturer of Hex. head and socket fasteners, wood screws, high tensile fasteners, nuts. Copper and Aluminium fasteners.

Distributor of complete range of fasteners

With exclusive dedication to manufacturing small metal parts, mainly washers, the company is currently one of the outstanding manufacturers in the European washers market.

From the customers drawing and based on applicable automotive standards, the company designs the process and carries out the entire process of manufacturing

Biggest factory in China producing stainless steel washers.

Fat washers, spring washers, tooth lock washers and stamping parts.

Materials: 316L ,316S33,1.4462.

Manufacturer of blind rivets, solid rivets, fully tubular rivets, semi tubular rivets, bifurcated rivets

Manufacturer of special cold forged fasteners. Blind rivets, rivets, semitubular rivets, nails for buttons and jeans, welding clavis pins

Manufacturer of blind rivets, semi tubular rivets, insert thread nuts, rivet tools

Manufacturer of standard and special washers in different materials, with internal diameter from 2.5 up to 80mm.

Manufacturer of solid, tubular and semi-tubular rivets, both standard and special. Barrel nuts and thumb screws

Distributor of retaining rings, Spiral retaining rings, wave springs, Disc springs, Washers, Elastic pins, Pins, Keys, Ground flat/bar stocks, Locking nuts, washers, Miniplast plastic parts, Metallic screws, nuts, bolts.

Manufacturer of washers and high quality safety shims. All materials: aluminium, bronze, iron and steel, stainless steel (A2, A4), copper, brass etc.

Manufacturer and distributor of all fixing products in the field of technical insulation

Producer of spring lock, toothed and special washers.

Quality Certificates: ISO 9001; ISO 14001; ISO/TS 16949

Manufacturer of standard flat washers ISOPLAC washers, also called pressure plates, used to secure insulation.

Manufacturer of speed rivets, blind nuts and blind rivets for automotive sector

Manufacturer specialized in spring washers in different materials, also with double rings

Manufacturer of washers, disc springs, wave spring washers, serrated safety washers, Belleville washers, serrated washers & lockrite washers.

Fastener manufacturing company with more than 15 years experience.

Production range: all kinds of flat washers, spring washers, toothed washers, square washers, custom special washers.

Materials: stainless steel, carbon steel, brass.

Manufacturer of stainless steel flat washers, spring washers, square washers, tab washers, toothed lock washers and stamping parts

Manufacturer of standard and special washers in steel, stainless steel, brass and copper

Manufacturer of semi-tubular rivets, solid rivets, forged parts, tubular rivets

Distributor and Exporter of fasteners specialized in standard and special washers

Manufacturer of stampings and flat washers in stainless steel, steel, non-ferrous metals and different kind of surface coatings

Importer/Wholesaler of fasteners in steel, stainless steel, brass, nylon and titanium.

Manufacturer of Plain Washers, Flat Washers, Spring Washers & Special Sheet Metal & Wire Components, Din 127, Din 125, Din 9021.

From 1970 we produce, following specification and drawings, turned parts for every industrial sector.

We can work with a wide kind of metals, i.e.:

- Inox solid steel

- Tied up steels

- Titanium

- Alluminium

- Copper alloy

- Brass alloy

Manufacturer of socket head screws, shoulder screws and dowel pins ranging from 4mm to 40mm diameter and lengths up to 400 mm in various grades (4.6, 5.6, 8.8, 10.9, 12.9, and 14.9).

Leading manufacturers and distributors of cold rolled coils and fasteners in the northern part of India. In our factory, we produce using up-to-date technology and ultra modern and highly advanced equipment.

Manufacturer of rivets and cold forged fasteners for the automotive and furniture industry

Manufacturer of hexagon bolts and screws (from M6 up to M42), hexagon nuts (from M6 up to M42), and solid rivets (Ø6 – Ø30). GOST Norms

Family-owned and managed in fourth generation, we are a leading European manufacturer of steel washers according to international standards and special stamped parts for mechanical connections.

Our customers are well-known fastener wholesalers and end users in the sectors of wind energy, steel construction, traffic engineering, railway engineering, agricultural machines and the automotive supplier industry.

Manufacturer of flat washers, combined washers, sealing washers, clamp washers, special washers and stampings

Manufacturer of solid, semi-tubular and hollow rivets in all materials.

Diameters from 1.3 to 10mm

Manufacturer of solid and semi-tubular rivets from diameter 1 mm to 10 mm. According to Din standards or on drawings

Manufacturer of solid rivets and half hole rivets, with sizes Ø1 mm – Ø6 mm up to 55 mm length.

Manufacturer specialized in washers. Production of 200,000 washers/day.

Flat, spring, toothed, square and wave washers, etc...

Manufacturer, exporter and supplier of special washers and sheet metal components.

Manufacturer of clamps, clips, linch pins, cotter pins, cage screws and nuts, wahsers

Division of Stanley group with several production units specialized in: blind rivets, threaded inserts, welding screws, sheet metal fasteners

Manufacturer of solid, tubular and semi tubular rivets bot standard and special in steel, stainless steel, aluminium, brass and copper.

Manufacturer specialized in all kinds of Plain Washers, Spring and wire washers, Circlips, Copper washers, Aluminum washers, Star washers, Conical star washers, Serrated washers, Conical washers, Spherical washers.

Manufacturer of flat washers, spring washers, toothed washers, contact washers, belleville washers, spring washers, retaining rings, stamping parts.

Manufacturer of washers, cotter pins, linch pins, circlips, dowel pins, eye screws and wing nuts

Universal Precision Screws is a leading fastener manufacturer in India, whose brand UPS Lakshmi is renowned for superior quality industrial and commercial fasteners. We excel in delivering high precision, speed and efficiency, in order to meet the dynamic market demands.

Manufacturer and distributor of screws and rivets

Sizes from0.8 mm to 8.0 mm. Maximum length of 60 mm. Materials: iron (Fe), stainless steel, aluminum (Al), copper (Cu), brass (CuZn)

Manufacturer of washers, stampings and spring-action washers and sealing washers with a variety of materials

Manufacturer of special washers and stampings in steel, stainless steel, alloy, copper, plastic

Manufacturer of stud bolts and fixing elements.

Stainless steel is our main material, and our wedge anchors feature manually machined characteristics.

Our core value is to produce customized and innovated wedge anchors based on your drawings. Our expansion clip is specially designed. Our products also include special bolts and flat washers.