Proveedores de Arandelas de muelle abombadas (forma A - forma B)

Datos técnicos

Arandelas de muelle abombadas (forma A - forma B)

Este producto está regulado por las siguientes normas:

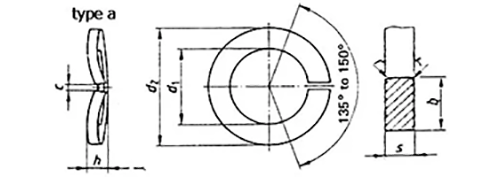

Standard DIN 128

Arandelas elásticas de seguridad curvas Las arand...Información restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| |||||||||

| Dimensions in mm - source DIN 128 - Withdrawn | |||||||||

| Publication date: 10/1994 - Supersedes DIN 128: 10/1978 | |||||||||

| d Nominal size | Thread size | d min | d1 max | b nom | s nom | h min | r | ≈ mass in Kg x 1000 pcs (ρ=7,85 kg/dm3) | |

| 2 | M 2 | 2.1 | 4.4 | 0.9 | 0.5 | 0.7 | 0.1 | 0.035 | |

| 2.5 | M 2.5 | 2.6 | 5.1 | 1 | 0.6 | 0.9 | 0.1 | 0.055 | |

| 3 | |||||||||

| 3.5 | |||||||||

| 4 | |||||||||

| 5 | |||||||||

| 6 | |||||||||

| 7 | |||||||||

| 8 | |||||||||

| 10 | |||||||||

| 12 | |||||||||

| 14 | |||||||||

| 16 | |||||||||

| 18 | |||||||||

| 20 | |||||||||

| 22 | |||||||||

| 24 | |||||||||

| 27 | |||||||||

| 30 | |||||||||

| 36 | |||||||||

| 42 | |||||||||

| 48 | |||||||||

| 56 | |||||||||

| 64 | |||||||||

| 72 | |||||||||

| 80 | |||||||||

| 90 | |||||||||

| 100 | |||||||||

| |||||||||

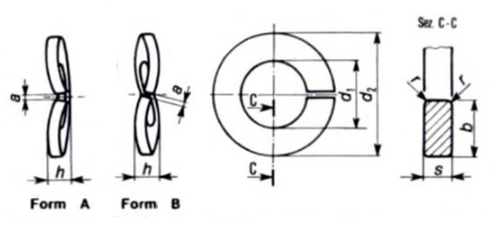

| Dimensions in mm - source DIN 128 - Withdrawn | |||||||||

| Publication date: 10/1987 - Supersedes DIN 128: 04/1968 | |||||||||

| Nominal size | Thread size | d min | d1 max | b | s nom | h min | r | ≈ mass in Kg x 1000 pcs (ρ=7,85 kg/dm3) | |

| 2 | M 2 | 2.1 | 4.4 | 0.9 | 0.5 | 0.7 | 0.1 | 0.035 | |

| 2.5 | M 2.5 | 2.6 | 5.1 | 1 | 0.6 | 0.9 | 0.1 | 0.055 | |

| 3 | |||||||||

| 3.5 | |||||||||

| 4 | |||||||||

| 5 | |||||||||

| 6 | |||||||||

| 7 | |||||||||

| 8 | |||||||||

| 10 | |||||||||

| 12 | |||||||||

| 14 | |||||||||

| 16 | |||||||||

| 18 | |||||||||

| 20 | |||||||||

| 22 | |||||||||

| 24 | |||||||||

| 27 | |||||||||

| 30 | |||||||||

| 36 | |||||||||

| 42 | |||||||||

| 48 | |||||||||

| 56 | |||||||||

| 64 | |||||||||

| 72 | |||||||||

| 80 | |||||||||

| 90 | |||||||||

| 100 | |||||||||

Standard UNI 8839

Arandelas de resorte abiertas curvas o onduladasInformación restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source UNI 8839 | ||||||||

| Publication date: 10/2013 - Supersedes UNI 8839: 04/1985 | ||||||||

| d1Nominal size | Thread size | d2 MAX | b nom | s nom | h min | h max | r | |

| 2.1 | M 2 | 4.4 | 0.9 | 0.5 | 0.7 | 0.9 | 0.1 | |

| 2.4 | ||||||||

| 2.6 | ||||||||

| 3.1 | ||||||||

| 3.6 | ||||||||

| 4.1 | ||||||||

| 5.1 | ||||||||

| 6.1 | ||||||||

| 7.1 | ||||||||

| 8.2 | ||||||||

| 10.2 | ||||||||

| 12.2 | ||||||||

| 14.2 | ||||||||

| 16.2 | ||||||||

| 18.2 | ||||||||

| 20.2 | ||||||||

| 22.5 | ||||||||

| 24.5 | ||||||||

| 27.5 | ||||||||

| 30.5 | ||||||||

| 36.5 | ||||||||

Detalles

Arandelas de muelle abombadas (forma A - forma B)

Lista completa de proveedores de Arandelas de muelle abombadas (forma A - forma B)

Leading manufacturer of stainless steel washers and compensation rings for ball bearings. Standard and special parts.

Biggest factory in China producing stainless steel washers.

Fat washers, spring washers, tooth lock washers and stamping parts.

Materials: 316L ,316S33,1.4462.

Manufacturer of blind rivets, solid rivets, fully tubular rivets, semi tubular rivets, bifurcated rivets

Manufacturer of standard and special washers in different materials, with internal diameter from 2.5 up to 80mm.

Manufacturer of washers and high quality safety shims. All materials: aluminium, bronze, iron and steel, stainless steel (A2, A4), copper, brass etc.

Producer of spring lock, toothed and special washers.

Quality Certificates: ISO 9001; ISO 14001; ISO/TS 16949

Manufacturer specialized in spring washers in different materials, also with double rings

Manufacturer of washers, disc springs, wave spring washers, serrated safety washers, Belleville washers, serrated washers & lockrite washers.

Fastener manufacturing company with more than 15 years experience.

Production range: all kinds of flat washers, spring washers, toothed washers, square washers, custom special washers.

Materials: stainless steel, carbon steel, brass.

Manufacturer of stainless steel flat washers, spring washers, square washers, tab washers, toothed lock washers and stamping parts

Manufacturer of Plain Washers, Flat Washers, Spring Washers & Special Sheet Metal & Wire Components, Din 127, Din 125, Din 9021.

Manufacturer specialized in washers. Production of 200,000 washers/day.

Flat, spring, toothed, square and wave washers, etc...

Manufacturer, exporter and supplier of special washers and sheet metal components.

Manufacturer specialized in all kinds of Plain Washers, Spring and wire washers, Circlips, Copper washers, Aluminum washers, Star washers, Conical star washers, Serrated washers, Conical washers, Spherical washers.

Manufacturer of flat washers, spring washers, toothed washers, contact washers, belleville washers, spring washers, retaining rings, stamping parts.

Manufacturer of washers, cotter pins, linch pins, circlips, dowel pins, eye screws and wing nuts

Manufacturer of special washers and stampings in steel, stainless steel, alloy, copper, plastic