Proveedores de Lifting eye bolts

Este producto está regulado por las siguientes normas:

DIN 580 UNI 2947 BS 4278-1 DIN EN ISO 3266 BS 4278-2 BS 4278-3

Datos técnicos

Lifting eye bolts

Este producto está regulado por las siguientes normas:

Standard DIN 580

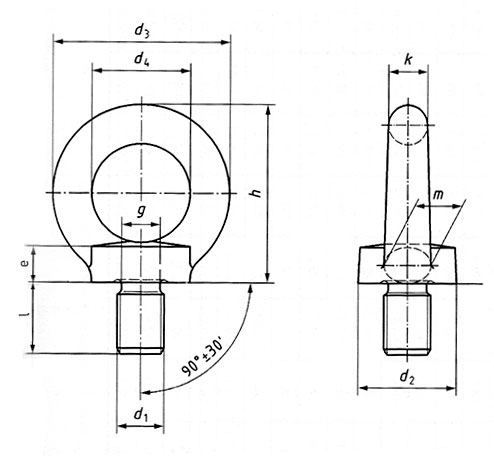

Cáncamos de elevación Esta norma especifica las ca...Información restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source DIN 580 | ||||||||

| Publication date: 04/2018 Supersedes DIN 580 09/2010 | ||||||||

| d1 thread size | d2 nom | d3 nom | d4 nom | e nom | g nom | l nom | k nom | m nom |

| M 6 | 20 | 36 | 20 | 6 | 4.4 | 13 | 8 | 10 |

| M 8 | 20 | 36 | 20 | 6 | 6 | 13 | 8 | 10 |

| M 10 | ||||||||

| M 12 | ||||||||

| M 14 | ||||||||

| M 16 | ||||||||

| M 18 | ||||||||

| M 20 | ||||||||

| M 22 | ||||||||

| M 24 | ||||||||

| M 27 | ||||||||

| M 30 | ||||||||

| M 33 | ||||||||

| M 36 | ||||||||

| M 39 | ||||||||

| M 42 | ||||||||

| M 45 | ||||||||

| M 48 | ||||||||

| M 52 | ||||||||

| M 56 | ||||||||

| M 60 | ||||||||

| M 64 | ||||||||

| M 72x6 | ||||||||

| M 80x6 | ||||||||

| M 100x6 | ||||||||

| DIN 580 2018 - Lifting capacity | |||||||||||||

| d thread size | M6 | M8 | M10 | M12 | M 14 | M16 | M 18 | M20 | M 22 | M24 | M 27 | M30 | |

| Lifting capacity, WILL kg 0° |  | 75 | 140 | 230 | 340 | 490 | 700 | 850 | 1200 | 1400 | 1800 | 2100 | 3200 |

| Lifting capacity, WILL kg 45° |  | 55 | 100 | 170 | 240 | 350 | 500 | 600 | 860 | 1000 | 1290 | 1500 | 2300 |

| Lifting capacity, WILL kg 60° | |||||||||||||

| Lifting capacity, WILL kg 90° | |||||||||||||

| DIN 580 2018 - Lifting capacity | ||||||||||||||

| d thread size | M 33 | M 36 | M 39 | M42 | M 45 | M48 | M 52 | M56 | M 60 | M64 | M72X6 | M80X6 | M100X6 | |

| Lifting capacity, WILL kg 0° |  | 3200 | 4600 | 4600 | 6300 | 6300 | 8600 | 8600 | 11500 | 11500 | 16000 | 20000 | 28000 | 40000 |

| Lifting capacity, WILL kg 45° |  | 2300 | 3300 | 3300 | 4500 | 4500 | 6100 | 6100 | 8200 | 8200 | 11000 | 14000 | 20000 | 29000 |

| Lifting capacity, WILL kg 60° | ||||||||||||||

| Lifting capacity, WILL kg 90° | ||||||||||||||

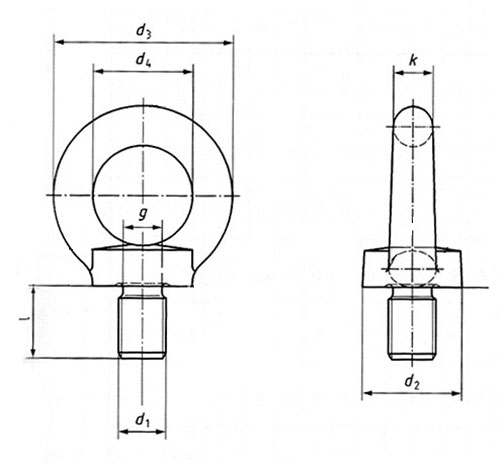

| Dimensions in mm - source DIN 580 | ||||||||||

| Publication date: 09/2010 Supersedes DIN 580 8/2003 | ||||||||||

| d1 thread size | WW thread | UNC thread | d2 nom | d3 nom | d4 nom | e nom | l nom | k nom | m nom | ~weigth, in kg x piece |

| M 8 | 1/4' | 1/4'-20 | 20 | 36 | 20 | 6 | 13 | 8 | 10 | 0.06 |

| M 8 | ||||||||||

| M 10 | ||||||||||

| M 12 | ||||||||||

| M 16 | ||||||||||

| M 20 | ||||||||||

| M 24 | ||||||||||

| M 24 | ||||||||||

| M 30 | ||||||||||

| M 36 | ||||||||||

| M 42 | ||||||||||

| M 48 | ||||||||||

| M 56 | ||||||||||

| M 64 | ||||||||||

| M 72x6 | ||||||||||

| M 80x6 | ||||||||||

| M 100x6 | ||||||||||

| Din 580 2010 - Lifting capacity | |||||||||

| d thread size | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | |

| Lifting capacity, axial per eye bolt kg |  | 140 | 230 | 340 | 700 | 1200 | 1800 | 3200 | 4600 |

| Lifting capacity per eye bolt ≤ 45° |  | 100 | 170 | 240 | 500 | 860 | 1290 | 2300 | 3300 |

| Lifting capacity per eye bolt, with bolt fitted at sides of load, ≤ 45° | |||||||||

| Din 580 2010 - Lifting capacity | ||||||||

| d thread size | M42 | M48 | M56 | M64 | M72X6 | M80X6 | M100X6 | |

| Lifting capacity, axial per eye bolt |  | 6300 | 8600 | 11500 | 16000 | 20000 | 28000 | 40000 |

| Lifting capacity per eye bolt ≤ 45° |  | 4500 | 6100 | 8200 | 11000 | 14000 | 20000 | 29000 |

| Lifting capacity per eye bolt, with bolt fitted at sides of load, ≤ 45° | ||||||||

Standard UNI 2947

Pernos de ojo de elevación, totalmente roscadosInformación restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source UNI 2947 | |||||

| Publication date: 12-1948 | |||||

| d1 thread size | d2 nom | d3 nom | d4 nom | l nom | k nom |

| M 8 | 20 | 36 | 20 | 13 | 8 |

| M 10 | |||||

| M 12 | |||||

| M 16 | |||||

| M 20 | |||||

| M 24 | |||||

| M 30 | |||||

| M 36 | |||||

| M 42 | |||||

| M 48 | |||||

| M 56 | |||||

| M 64 | |||||

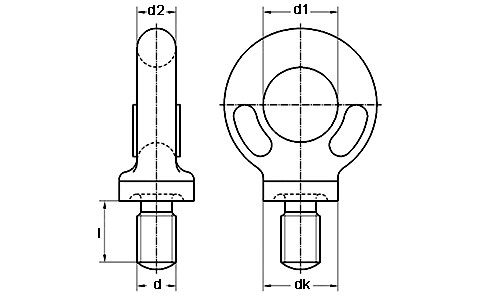

Standard BS 4278-1

Pernos de ojo de collar para fines de elevaciónInformación restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source BS 4278-1 Withdrawn | ||||

| Publication date: 04/1984 | ||||

| d thread size | dk | d1 | d2 | l |

| M 12 | 22 | 15 | 9 | 18 |

| M 16 | ||||

| M 20 | ||||

| M 24 | ||||

| M 30 | ||||

| M 36 | ||||

| M 42 | ||||

| M 48 | ||||

| M 52 | ||||

| M 56 | ||||

| M 64 | ||||

| M 72 | ||||

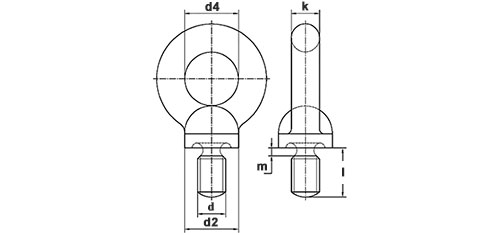

Standard DIN EN ISO 3266

Cáncamos de acero forjado grado 4 para fines gener...Información restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source DIN EN ISO 3266 | ||||||

| Publication date: 05/2016 | ||||||

| d1 thread size | d2 nom | d4 nom | l nom | k nom | m nom | |

| M 8 | 17 | 9 | 12 | 6 | 2 | |

| M 10 | ||||||

| M 12 | ||||||

| M 16 | ||||||

| M 20 | ||||||

| M 24 | ||||||

| M 30 | ||||||

| M 36 | ||||||

| M 42 | ||||||

| M 48 | ||||||

| M 52 | ||||||

| M 56 | ||||||

| M 64 | ||||||

| M 72 | ||||||

| M 80 | ||||||

| M 90 | ||||||

| M 100 | ||||||

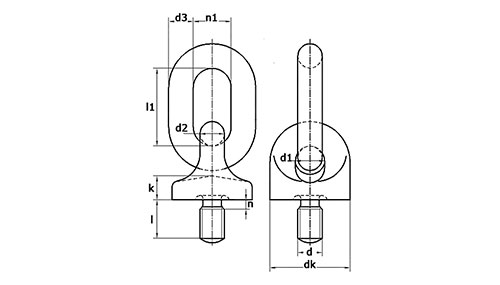

Standard BS 4278-2

Perno de ojo con enlaceInformación restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source BS4278-2 Withdrawn | |||||||||

| Publication date: 04/19847 | |||||||||

| 9d thread size | dk | d1 | d2 | d3 | n | l | k | n1 | l1 |

| M 20 | 39 | 15 | 12 | 13 | 4 | 27 | 12 | 24 | 53 |

| M 24 | |||||||||

| M 30 | |||||||||

| M 36 | |||||||||

| M 48 | |||||||||

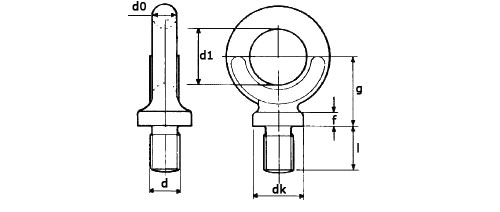

Standard BS 4278-3

Perno de ojo de dinamoInformación restringida a los usuarios inscritos: Login | Regístrate ahora para una prueba gratuita de 14 días.

| Dimensions in mm - source BS4278-3 Withdrawn | ||||

| Publication date: 04/1984 | ||||

| d thread size | dk | d1 | d0 | l |

| M 12 | 17 | 22 | 9 | 18 |

| M 16 | ||||

| M 20 | ||||

| M 24 | ||||

| M 30 | ||||

| M 36 | ||||

| M 42 | ||||

| M 48 | ||||

| M 52 | ||||

Detalles

Lifting eye bolts

Lista completa de proveedores de Lifting eye bolts

Manufacturer of wing nuts AF, wing screws AF, thumb screws, toothed plate connectors, beam clamps, channel, hexagon (domed) cap nuts

Spanish company manufacturing threaded rods and anchor bolts, with more than 40 years of experience in this field.

Production range: M-4 to M-80, in lengths from 20 mm to 6 meters in quality 4.8, 5.6, 6.8, 8.8, 10.9, 12.9 and stainless steel A2.

Manufacturer of cold forged parts: eye bolts, t-head bolts and clevis pins in steel and stainless steel.

Diameter 5–16mm and lengths up to 180mm

Manufacturer of hot forged fasteners, Eyebolts, shackles, holding down blts, U-bolts, hammerhead , T- Bolts and Special Bolts.

Hot forged parts from M10 to M100 and up to 6000 mm length.

Producer and distributor of many kinds of standard and nonstandard fasteners. Competitive products are: threaded rods, U bolts, nuts, washers, stampings parts, screws, bolts, chains, riggings, rivets, anchors. Material can be carbon steel, stainless steel, brass, nickel alloy and Titanium.

Manufacturer specialized in eye bolts, eye nuts and turnbuckles, both standard and special.

We operate in the production of lifting accessories, customized forged parts in steel and CNC-processing/machining. We also offer technical know how in the complex field of forging technology.

Certified following DIN 9001.

Manufacturer of hooks, eyebolts, U-bolts, studs, log bolts, foundation clamps, rods, pins, tie-rods, threaded bars and special chamfered-end bars

Manufacturer of parallel keys in metrich and inch sizes, clevis yokes, eye bolts and studs with hole.

Manufacturer of round steel chains, forged link chains, steel link chains and chain wheels in all dimensions, materials and standards.

Lifting accessories.

Distributor of chains, wire ropes, lifting accessories, eye nuts, shackles, turnbuckles and hooks

Distributor of lifting accessories, chains, hose clamps and nautical fixings in stainless steel

Manufacturer of lifting & rigging hardware, fasteners, CNC machined parts, stamping parts and custom industrial parts

Manufacturer and exporter of chains and lifting accessories: hooks, shackles, wire rope clips, turnbuckles, etc..

Exporter of lifting equipment, hooks, shackles, turnbuckles, chains and wire ropes.

Manufacturer specailized in lifting accessories: eye bolts, wire rope clips, shackles, turnbuckles, hooks, chains and wire rops.

Manufacturer of shackles, turnbuckles, clips, hooks, rings, thimbles, chains, stainless steel and marine hardware

We are a company specialized in the production of pipe clamps in small and big sizes and we can offer additional manufacturing, coatings, pre-assembly and Packing.

We manufacure

- Hose clamps

- Round steel bars, flat steel bars

-Pipe slides with accessories

- Tube supports following the customers requirements, drawings, samples in all standard norms.

Take time and feel free to ask for our offer and possibilities.

Manufacturer of nautical fixing products and lifting accessories in stainless steel